Aston Martin will race a hydrogen fuelled car in this years Nurburgring 24 Hours. It will be the first hydrogen-powered car to compete in an international event as well as the first zero CO2 emissions vehicle to complete a race pace lap at the Nürburgring 24-hour race. The Hybrid Hydrogen race car is based on the new Rapide S four-door sports car.

Working in partnership with hydrogen experts Alset Global, Aston Martin’s engineers have developed a prototype twin turbocharged 6.0-litre V12 engine that will power the Nürburgring car. Capable of running on pure gasoline, pure gaseous hydrogen, or a blend of both, the Hybrid Hydrogen race car showcases Aston Martin’s commitment to engineering innovation. In pure hydrogen mode, Aston Martin and Alset Global aim to show that a zero CO2 emissions lap of the Nordschleife is possible whilst emitting virtually only water from the exhaust pipe.

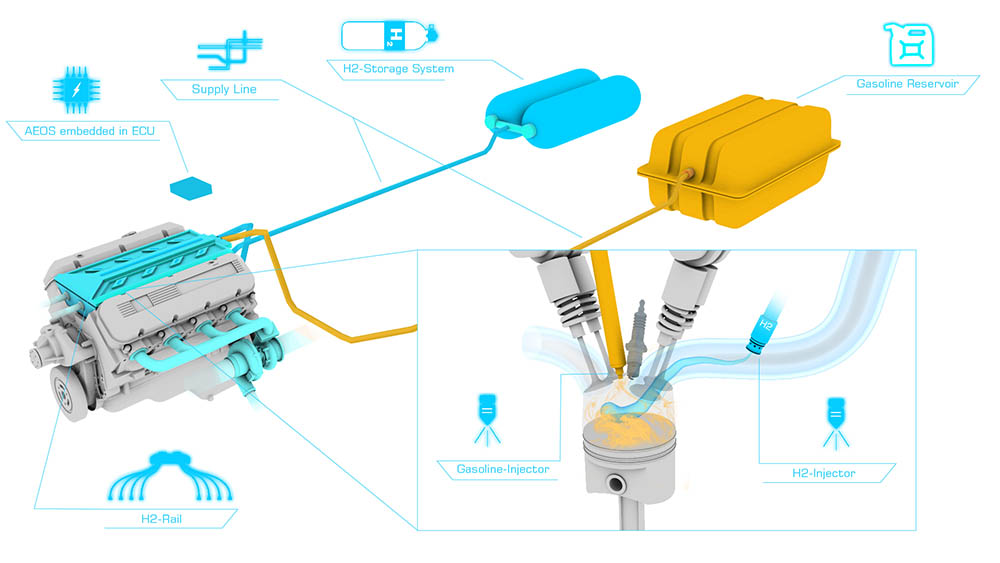

Alset Global’s unique Hybrid Hydrogen system allows a vehicle to run on hydrogen, gasoline or a blend of both fuels, depending on the driving request, and ensures an optimum balance between power, acceleration and CO2 reduction. The system comprises the hydrogen storage system, a hydrogen supply and injection system, a safety system and an engine control unit (ECU). The ECU contains the proprietary Alset Engine Operating Software (AEOS) that controls fuel compounding and the combustion process according to each particular driving situation. In circumstances where more power or torque is required, the system can automatically blend a small amount of gasoline in with the hydrogen to offer a ‘boost’ feature.

Aston Martin Rapide S race car is equipped with four carbon-fibre hydrogen storage tanks – two housed next to the driver and two in the trunk of the car – holding a total of 3.2 kg, which equivalent to 12 litres of gasoline. In the race car, the hydrogen is stored at a pressure of 350 bar for a simple and quick refuelling. In a production version of the vehicle, however, 700 bar pressure storage is possible and allows for smaller packaging or for higher amounts of fuel to be stored. The Rapide S race car is equipped with a 100 litre motorsport- specified gasoline tank in its regular position, providing a total combined range of nine laps on the Nordschleife and resulting in no range disadvantage during the race.

The hydrogen system, together with engine enhancements (see below), adds approximately 100 kg to the weight of the car. Approximately 70 per cent of the additional weight is due to the tanks.

Hydrogen storage system. The four 350 bar hydrogen tanks are fully wrapped composite cylinders with an aluminium liner with a 15 mm thickness. These cylinders are denominated Type III cylinders and all vessels together have a total hydrogen storage capacity of 3.2 kg.

The storage system was developed together with Magna Steyr. The whole system weighs around 100 kg including all components and including cylinders (two weighing 21 kg and two weighing 17 kg), valves, holding brackets for front and rear, tubes and a pressure regulator unit.

The packaging was specially designed to fulfil all safety regulations and to avoid any sort of damage during the race.

Hydrogen safety and tank control. An ECU, developed together with our partner Gigatronik, monitors and manages the Hybrid Hydrogen safety and tank system on the car. A safety concept has been developed that considers the specific properties of hydrogen as a fuel and ensures maximum safety in all racing conditions. The hydrogen ECU is connected to four hydrogen sensors which continuously monitor the gas system, and to crash sensors. In the event of one of the sensors detecting a trace of hydrogen, or if there is a crash, the hydrogen supply will immediately shut off. A valve between the tank and the pressure regulator closes and all the hydrogen, beside the amount left in the pipes, is retained within the extremely robust carbon fibre composite storage cylinders.

The safety system allows the Hybrid Hydrogen vehicle to be as safe as any other vehicle in the race. Crash safety has been ensured by carrying out crash tests of the conventional Rapide S as a part of the standard homologation process. Relevant modifications of the conventional vehicle were developed according to the results of crash simulations.

The TÜV SÜD has certified the technical safety measures for the hydrogen system and oversaw the approval of the system for the race environment.

Integration

Crucially for a seamless introduction, Alset Global’s Hybrid Hydrogen system requires no major changes to the internal combustion engine.

The mixture formation system was redesigned and a hydrogen rail, injectors and a turbo charger unit were integrated, considering the specific thermodynamic properties of the hydrogen combustion process. Since the modification effort of the base engine is low, it is feasible to retrofit virtually any engine, including direct injection engines. The development of the Aston Martin Hybrid Hydrogen Rapide S was completed in under 12 months.

The minimal adaptations are mostly responses to a reduction in engine power when operating in pure hydrogen mode, due to the lower volumetric energy density of hydrogen fuel. With 560 hp, the Aston Martin Hybrid Hydrogen Rapide S represents the most powerful hydrogen car that has ever been built.

Twin turbochargers.

Two small exhaust driven turbochargers are used when the car is burning hydrogen to improve the mixture heating value of the charge, forcing more air/fuel mixture into the combustion chamber. To facilitate the intercooler package, the front grille of the new Rapide S has been slightly adapted and features scoops on the left and right side. As the car industry moves increasingly to turbocharged engines, this package modification is unlikely to be required for all commercial applications in the future.

Compression ratio.

To facilitate turbo charger operation the compression ratio has been reduced from 11.5:1 to 9.5:1, achieved through a modification to the piston crown design. The integration of the turbo chargers also led to an alternative cylinder head gasket.

Valves.

Due to a lack of lubrication properties of the hydrogen fuel, it might be necessary to use different materials for the valves or/and the valve seats. The Aston Martin Hybrid Hydrogen Rapide S’ valves are made from Inconel alloy for added robustness and improved temperature resistance.

Engine ECU.

As custom software was required for this one-off race car, the flexible motorsport Pectel engine management system from Cosworth is used. For road car applications though, a standard OEM ECU would be used. In order to control the engine in all modes, specific engine control functionalities developed for the Alset Engine Operating Software (AEOS) have been integrated with the Pectel controller.

Hydrogen injection system.

The hydrogen injectors, supplied by AFS, are similar in design to natural gas injectors found in OEM CNG applications. There are small differences needed for the different requirements, including high durability seals and materials. In the case of the Aston Martin V12, those injectors, of a solenoid type, are fitted to the intake manifold, upstream of the regular gasoline injectors. The hydrogen is delivered to the fuel rail in constant flow, at between 4 and 5 bar.

read more here