Formula E teams are testing laboratories to traditional oil companies for developing and providing of the new generation of lubricants.

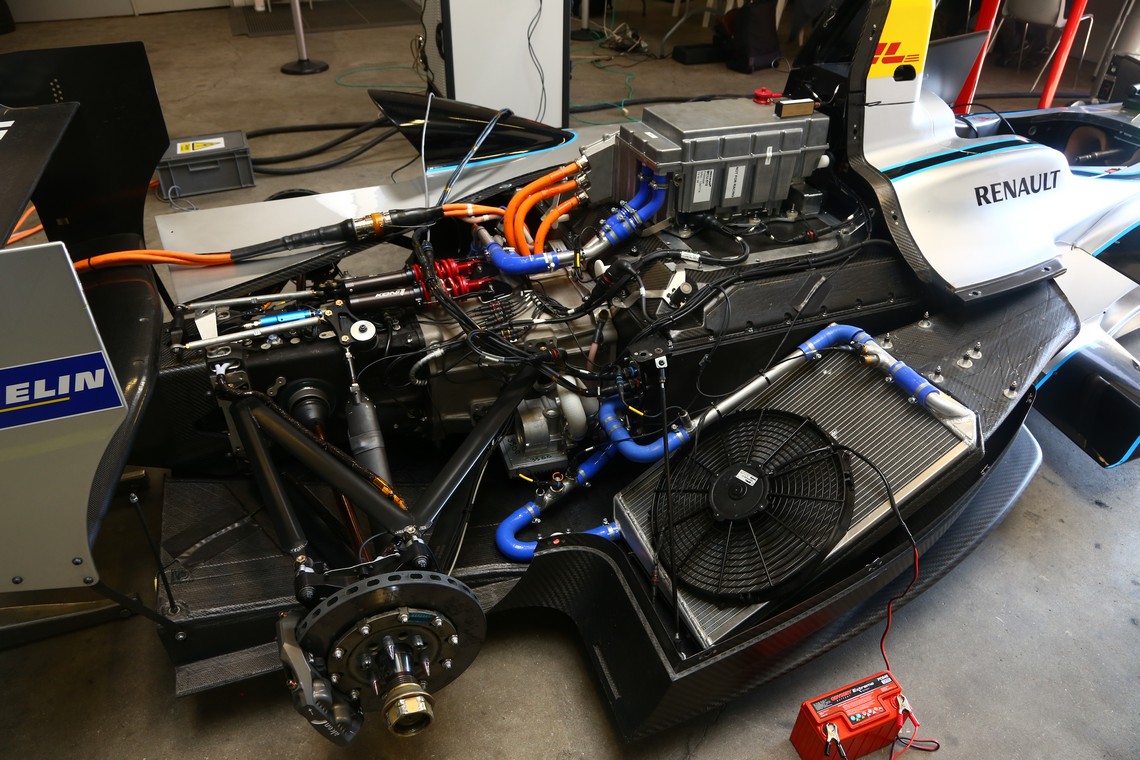

Formula E as a fairly new racing championship is a perfect platform for testing and development of new technologies, solutions and products for this new wave of electrification and transportation in general. These high-tech racing machines demand different properties from fluids and lubricants and challenges need to be met. In general oil companies have three different product groups for electric vehicle (EV) fluids and lubricants: thermal fluids, transmission fluids and greases.

E-vehicle (EV) fluids and lubricants have their own traits, attributes and can be best explained by putting them in four categories:

- Electrical insulation that fluid with dielectric properties must provide because is constantly in contact with electronic and electrical components.

- Another important trait to be met by this E-vehicle (EV) fluids is their compatibility with different type of materials especially copper as a key material applied in E-vehicle (EV) systems.

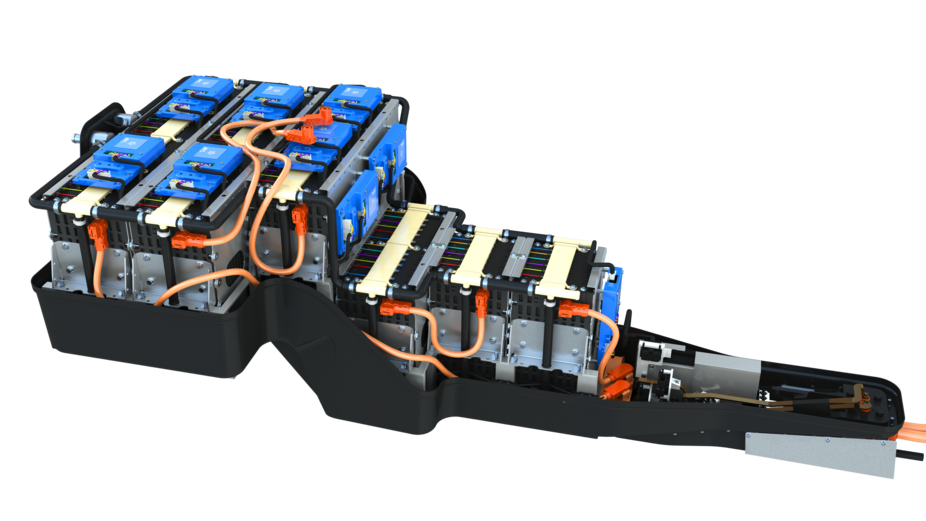

- Thermal properties of the fluid and lubricants are of the paramount importance for new E-vehicles (EV). And Formula E cars are even greater challenge for them because they are such a tightly packed with battery, e-motor and gearbox working under severe heat conditions. Fluids must keep the right temperature that way they provide optimum working conditions. Performance is still the key in Formula E and for that they must operate in desired temperature range. Power units in Formula E produce enormous heat which dissipate electrical energy from components (this is called Joule effect). Energy means power so fluids must ensure precise heat evacuation.

With battery immersion technology that is used in Formula E thermal fluids with dielectric properties are pumped and reach every battery cell, directly absorbing the heat. Immersion cooling in Formula E is provided by Mclaren and Lucid Motors (formerly Atieva) as a common suppliers and comes with many advantages: longer battery life, it is space saving and it provides better and more efficient cooling.

- Friction properties and some standard lubricant function of the E-vehicle fluids are challenges important in the area of mechanical protection of some parts, limiting the wear, oxidation and corrosion.

In the near future with demand for engineering and design of a more compact electric vehicles (EV) and power trains, development and properties of fluids and lubricants will follow that path and oil companies have new R&D directions and guidelines.

Here is the link of interview with Shell head of strategic partnership Jeanine Bakx, explaining their role and strategic partnership with Formula E team Nissan e.dams.